Joist dimensions

Posi joists can be manufactured in various heights. According to the structural engineering specifications or desired gap width for installations, different sizes of webs are available. From PS 8 upto PS 16. In correlation with the selected web size the overall height of the of the entire Posi joist beam relates.

| Type | gap between cords [mm] | Overall height [mm] |

| PS 8 | 108 | 202 |

| PS 9N | 134 | 225 |

| PS 10N | 159 | 253 |

| PS 12 | 210 | 304 |

| PS 14N | 282 | 373 |

| PS 16N | 330 | 421 |

Gaps & Layer for services

The gaps between the webs and chords allow to run services for gas, water, sewage, electricity, heating, ventilation and such like. Individual dimensions and shapes might differ from the provided square or round.

| Type | A [mm] | D [mm] | Quadrat [mm] | Rectangular H [mm] | ||||||

| 50 | 75 | 100 | 125 | 150 | 175 | 200 | ||||

| Rectangular W [mm] | ||||||||||

| PS 8 | 108 | 105 | 95 | 270 | 180 | 90 | ||||

| PS 9 | 134 | 130 | 115 | 310 | 240 | 180 | 100 | |||

| PS 10 | 159 | 150 | 135 | 320 | 270 | 210 | 160 | 80 | ||

| PS 12 | 210 | 190 | 155 | 350 | 310 | 260 | 210 | 160 | 110 | 70 |

Posi joist end and bearing

The end of the Posi joist beam offers two different design options:

1. Framed and fixed with conector plates.

2. Solid timber or plywood bar, up to 500 mm length on each end. This strengthens the bearing and allows to transfer higher loads. Second it offers to length cut the posi joist on site.

Another option to improve the loadcapacity are double webs, reenforcing the end or in between with an extra single web. Optional the orientation of a full V-shape web might be changed in order to have two full webs very close to each other. Finaly the spacing between the joist might be shortened to gain more direct load taking joists per m².

Floor system

Improved load distribution and load bearing

The MiTek engineering software provides the timber section for the strong backs and the exact fixing points at the single joists. In case of a spliced strong back, the size and type of splice plate required is generated automatically. Alternatively splices from timber or plywood might be used on site. The software specifies those optional as well.

To improve the load bearing, the loads can be distributed more evenly over several joists by introducing "strong backs". To fix the strong back on the joist, preassembled metal hangers are used. Alternatively timber blocks might be used for onsite reenforcement, being nailed to the flanks of the joists cords.

Unsupported span and load assumptions

Load assumption for below table:

Traffic load: 2 kN

Dead load: 2 kN (Concrete top floor)

Bearing: Flat on bottom cord.

Beam end: Framed or trimmable (soild timber bar infill 500mm)

Timber section of cords: 47 mm x 72 mm up to 47 mm x 147 mm

| Type | Joist height [mm] |

Spacing [mm] | Max, unsuported free span [mm] due to load assumption | |||

| 47 x 72 | 47 x 97 | 47 x 122 | 47 x 147 | |||

| PS8 | 202 | 400 600 |

3500 2750 |

3750 3000 |

3900 3000 |

3900 3000 |

| PS9 | 225 | 400 600 |

3500 3000 |

3900 3200 |

4200 3200 |

4400 3200 |

| trimmable | 600 | 3400 | 3750 | 4000 | 4250 | |

| PS10 | 254 | 400 600 |

3900 3000 |

4000 3200 |

4400 3400 |

4600 3400 |

| PS12 | 302 | 400 600 |

4000 3000 |

4000 3000 |

4250 3000 |

4250 3000 |

| PS12N | 302 | 400 600 |

4200 3200 |

4700 3200 |

4800 3600 |

5000 3700 |

| trimmable | 600 | 3750 | 4000 | 4250 | 4500 | |

| PS14 | 373 | 400 600 |

4250 3200 |

4250 3200 |

4250 3200 |

4250 3200 |

| PS16 | 421 | 400 600 |

4500 3300 |

4500 3300 |

4500 3300 |

4500 3300 |

In accordance to the load assumptions of the subfloor and flooring (dead load) and traffic load, the unsuported free span of Posi Joist can exceed 6 meters. The max. standard production length is 11 meters which might be exceeded by using an extended press in / out feed.

Noise protection

Posi joists are capable of carrying heavy loads, like heavy subfloors while providing excellent air and body sound insulation values. Posi joists are suitable as a ceiling / floor system for multistorey apartment buildings, hotels, office buildings or family homes.

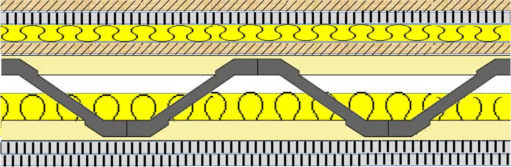

Floor detail for Rw 59 dB / Ln,w 57 dB

40 mm screed, 1950 kg/m², Moister barrier, 25 mm timber fibre floor sheeting ,270 kg/m³, 10 mm step noise insulation ,28 kg/m³, 5 mm protection folio seeling, 22 mm flooring chipboard T&G (650 kg/m³), PS 10 , cords 47mm x 70mm , C24, Noise spacer C profile, 15 mm gypsum board (12,5 kg/m²), 15 mm gypsum board (12,5 kg/m²).

Partially infill with minerall wool insulations, improves the noise protection adn fire, resitance of the Posi joist floor.

Fire resistance

Fire testing has proved that Posi joist floor systems fulfill 60 minute fire resistance criterias with out any extraordinary efforts. The testing provided fire from below. Tested according to BS 476:Teil 21:1987 and an applied traffic load of 2 kN/m².

Floor detail for F 60

18 mm flooring chipboard T&G; 19 mm gypsum board, fire rated; 25 mm step nois insulation, 36 kg/m²; 18 mm flooring chipboard T&G; PS 8 Posi joist, cords 97mm x 47mm; 100 mm Rockwool, 28 kg/m³; 12,5 mm gypsum board, fire rated; 12,5 mm gypsum board, fire rated.

Production length and spliced cords

Posi joists may be manufactured in any length. The top and botom chord may be spliced using standard timber trade length ranges or mixing stock material of various length, minimizing cut off waste. Splice joints are to be fingerjointed or jointed using MiTek connector plates type M 20.

The exact position of the splice joint may be defined in the MiTek design software and be structuraly engineered. This guarantees that always the most efficient design length can be applied, while the timber usage is still optimized to existing stock length or trade ranges.